Why is the pasteurization of biomasses becoming more and more a required practice for biogas and biomethane plants?

In many countries the regulations for specific biomasses (eg: animals and vegetables organic waste, industrial and municipal slurries, etc …) require that a pasteurization treatment be carried out before they are loaded into the digesters. A particular case is given for example by France where the regulations on the pasteurization of agricultural sewage destined for anaerobic digestion are becoming increasingly stringent.

Read the article by Green Laws Avocat here to further understand »

What are the limits of conventional pasteurization technologies?

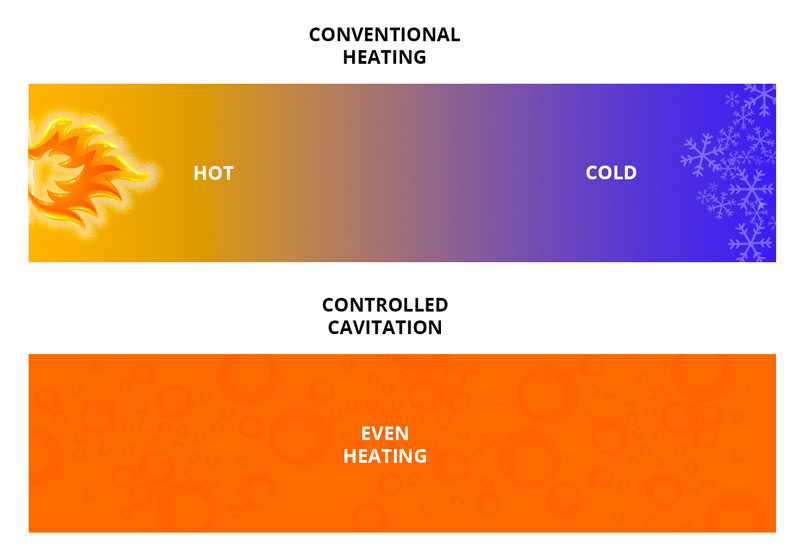

The classic pasteurization systems such as plate or spiral heat exchangers (etc …), using hot / cold heat exchange surfaces, have a low efficiency due to the creation of a temperature gradient between cold and hot areas and to the increasing viscosity of the product. Moreover, their performance is often compromised by the formation of deposits or encrustations on the exchange surface which further limit their efficiency.

What benefits can you get from introducing BioBANG for the application of pasteurization in your projects?

BioBANG, using the physical energy of controlled cavitation, transfers heat directly and homogeneously to the mass, without a thermal gradient, leading to the pasteurization temperature in a single step.

Furthermore, since there is no mechanical intermediation, BioBANG® maintains its high effectiveness even with very viscous products, without the formation of crusts and deposits. The system is flame-free, therefore without the use of combustion heating units, and can be fully automated.

With BioBANG® the pasteurization temperature can be adjusted with extreme accuracy by simply varying the number of rotor revolutions and the control can easily be performed through a temperature regulator and a frequency variator.

If national regulations require precise times for the product to be subjected to pasteurization, BioBANG® can be installed in batches to recirculate the product and thus guarantee constant temperature maintenance for the entire time necessary for pasteurization.

Finally, in addition to the pasteurization effect, BioBANG® allows at the same time to break up and instantly homogenize the product that is being loaded into the digesters. In this way it is possible to combine the pasteurization process with the pre-treatment process in a single technology to obtain a significative viscosity reduction, the complete miscibility and maximum digestion of the pasteurized biomass, once loaded inside the plant!

Watch the video to understand how the physical energy expressed by the cavitation effect of BioBANG® allows to improve the quality and efficiency of pasteurization:

Latest updates

- BioBANG connected to the cogenerator of a biomethane plant

- BioBANG: The unique, innovative and disruptive solution to maximise the efficiency and sustainability of biomethane plants

- Viscosity control: the key to keep the efficiency of your biogas/biomethane plant always high

- Reducing digestate viscosity to optimize the dehydration process in centrifuges

- BioBANG® announces the commissioning of a new unit in France